German Engineering 4.0

“NETWORKING IS ESSENTIAL”

PROFESSOR GÜNTHER SCHUH ON THE OPPORTUNITIES OF INDUSTRY 4.0 FOR SMES, THE COMMERCIAL VEHICLE OF THE FUTURE, AND THE IDEAS THAT HAVE LONG MADE THE TRANSPORT INDUSTRY A PIONEERING SECTOR OF THE GERMAN ECONOMY.

PROFESSOR, FOUNDER AND INDUSTRIOUS VISIONARY

Electric vehicles, battery cells and recently even air taxis – Professor Günther Schuh, born in Cologne in 1958, is driving innovative projects to the mass-production stage. The professor of Production Engineering at RWTH Aachen University doesn’t stop at schools of thought. With his electric mail vehicle named StreetScooter, he actively shook up the automotive industry. Since then, he now produces the e.Go, an electric city car with a dynamic design that costs around 12,000 euros. Most recently, the enterprising professor helped Armin Laschet, the minister president of the German state of North Rhine–Westphalia (abbreviated NRW), convince the country’s federal government to build the research factory for battery cells that it intends to fund with 500 million euros in the state. Günther Schuh is an enthusiastic amateur pilot, and is working on getting

innovative hybrid electric air taxis – which are virtually silent and can reach speeds of up to 300 km/h – off the ground in Aachen as early as the year 2024.

Professor Schuh, how do you think the transport and logistics industry will develop over the next ten years – and what changes will vehicle manufacturers and transport companies have to adapt to?

There are two areas in which I think we need to make massive improvements: congestion and emissions. One way to deal with traffic jams, for example, is to change the times when goods are transported and delivered, like delivering food to supermarkets at night. This will only be possible, however, if the entire delivery and also the loading and unloading process are carried out very quietly. Furthermore, at least in an urban environment, driving not only needs to be quiet, but also emission-free or at least low-emission. This is why I expect that in the future, we will also be using very different drive concepts for commercial vehicles in the transport industry than in the past. When it comes to heavy trucks, this will not be achieved solely using electric batteries, but instead will require hybrid drives, for example in the form of supplementary fuel cells as range extenders.

“No one can invent anything of significance to our society or economy on their own today.”

So we’re going to need innovative products. Where do you personally get the courage to carry out completely new vehicle and mobility projects? After all, you’re competing with established global corporations.

I view this less as competition, but instead continue to see myself primarily as a researcher. At some point I realized that if you only write publications or give lectures on concepts, you won’t get the attention you need to test concepts on a large industrial scale. e.GO Mobile AG, which was founded based on the research we began at RWTH Aachen University, provides us with the necessary infrastructure and, above all, the financial means to reach a base level from which we can launch mobility concepts such as what is currently the most affordable small electric vehicle on the market. So for the time being, I can

only be pleased that our concepts are attracting much more attention and that we are already provoking the creation of collaborators, copycats and perhaps future competitors in many areas – which is good for the industry as a whole.

By founding this company, you’ve created a unique infrastructure for the development and construction of new vehicles that has its origins in RWTH Aachen University. In addition, you not only have extensive knowledge of the market and technology, but also cultivate excellent contacts in politics and in the vehicle and supplier industries. How important are such networks for your work?

They are essential. Today no one can invent anything of significance to our society or economy on their own anymore. We always need a concerted effort from larger corporations, but often also beyond that, and as a small player you are sometimes not that successful. Thanks to our RWTH Aachen campus, we can attract many companies who are just as curious and innovative and who first want to test something out with us in order to create a proof of concept. Then the quality of the discussion is quite different. If you need partners for this process from large companies who work at the upper management level and are courageous enough to try something new, then of course it helps if you already have a trusting relationship with these individuals. If you don’t know each other, the CEO of a technology company might think: what does this professor think he can tell me from his ivory tower? But if you know each other and they believe you can produce useful results, it’s much easier.

Germany is a nation of small and medium-sized businesses, especially in the automotive supplier and transport vehicle industries. Many are highly specialised and have outstanding expertise, but find it difficult to establish access to innovative initiatives and networks in addition to their day-to-day business. Will the future of transport only be written by the major players?

I know that many SMEs like to hide their light under a bushel and say: “We can’t do it all like the big boys.” But the reality is different, as you can see at BPW, for example. After all, how many groundbreaking innovations has BPW brought to market – and done so faster than most of its major competitors or customers would have achieved! This is what makes Germany’s mid-sized sector so special. It is not only large and well-represented, but also highly qualified when it comes to technology. If we then look at the shift to industry 4.0, I no longer see any shortcomings in the development of small and medium-sized enterprises in Germany.

“New business models need a clear value proposition. The commercial vehicle sector is already showing many other industries how it’s done.”

But to what extent is Industry 4.0 applicable to small and medium-sized vehicle manufacturers at all? Unlike car production, trailer construction is highly specialised. This means a considerable amount of manual work – both in design, assembly and business processes. How can vehicle manufacturers get started with Industry 4.0?

Industry 4.0 is particularly helpful in such cases because it does not simply refer to “automation” in the sense of roboticised mass production, but to digitally connecting the most important application systems from development, production planning and control as well as from the supply chain. If I want to build a customised solution, it is crucial that I never have to start from scratch, but instead can build on a platform based on my previous designs and experience. This is because almost everything I do for my customers, every application I develop, benefits greatly from previous projects in terms of robustness, quality and maturity. After all, I can then draw on all the data and past experience and, for example, the change and improvement management of previous versions.

behind it. It turns recovered braking energy into electricity.

In this respect, being able to build on an Industry 4.0 infrastructure makes this kind of customer-specific production a much better service even as early as the customising process, and it also benefits the customer because I can then use this data backbone for aftersales. I know exactly what I have built into the customer’s solution in each individual case, and can, for example, determine when working on a future version whether it can be upgraded etc. Today, all of these parameters across the application system are part of the overall process, not just collected as master data in the ERP. They make customising much more efficient and are therefore not only suitable for mass production of passenger cars, but also for individual and small-batch production in the truck and body business.

Industry 4.0 not only means connected production, but also connected business models – and partnerships outside of the traditional “vertical thinking”. In this respect, is the established industry in Germany more lacking in courage or more in resources?

I believe that the target vision of the new business models is not really clear to us and that we are therefore digitising and integrating the individual application systems to a greater extent, but do not yet have a complete picture of what we can achieve with them. The new business models can seek to deliver an even more concrete, reliable value proposition. The commercial vehicle sector is a

particularly good example of an industry that’s already showing many others how it’s done. If the typical fleet buyer today needs 120 vehicles during peak periods, they buy 100 trucks from an OEM and rent the remaining 20 on the days and in the weeks when demand peaks. As a result, they are, in a sense, buying themselves a certain degree of guaranteed mobility.

Such a subscription model is one of the new possibilities that digitisation can offer to ensure that both the customer and the supplier know much more precisely what the customer needs, when it needs it and where it needs it. If this helps us reduce overcapacities and make even more efficient use of the overall system, then we see what still needs to be achieved through new business models. In recent years, the commercial vehicle industry has been a particularly great example of how to take advantage of this in day-to-day operations, for example by starting to consistently minimise empty running.

“BPW innovates faster than major competitors.”

If we look at today’s trucks, we see a driver perched high above the road – with a powerful diesel engine below them. What do you think he transport vehicle of the future might look like?

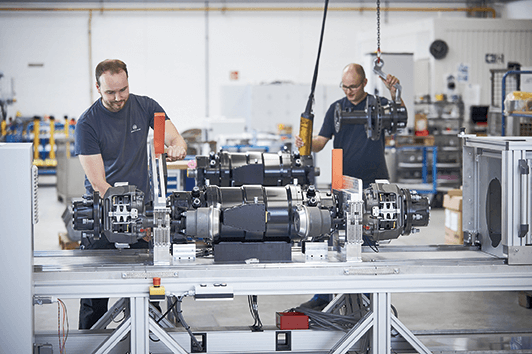

It would be awesome if we could use the benefits of a different power train to get more cubic metres of cargo into the same amount of space – not with all vehicles, but with many, especially those where volume is more important than weight. If we imagine, for example, that we have an electric-powered truck equipped with a medium-sized battery and a hydrogen-powered fuel cell, then I suppose the truck driver will no longer sit perched above the engine because the engine no longer exists. The engine is much more compact and would ideally be integrated into a vehicle axle – just like BPW is doing right now. So the driver would sit much lower. They would drive more like in a car – only with a large trailer behind them. This means you can also create additional cargo space above the driver. This would allow us to utilise the space in the truck of the future much more efficiently and thus also make the transport service much more economical.

So it would be another important step towards greater efficiency?

Absolutely! I believe that these steps are precisely the way to make a substantial improvement in terms of both economics and the environment. To achieve this, however, the intelligent drive concept must also be designed to suit the respective application. For example, an electric-powered truck could be equipped with a fully integrated axle that carries the load, i.e. the motor or motors, and other components could be eliminated, such as the differential. This would make the vehicle far more efficient – and this presents a tremendous opportunity for the transport vehicle of the future.

“An engineer really just wants to make the world a better place.”

An electric transport vehicle today needs to do more than just drive from point A to point B. To what extent do we need to reconsider transport processes themselves? And what kind of change, what kind of shift in thinking will this require from the transport companies, i.e. the hauliers?

I believe that we need to optimise the multimodal transport system as a whole. In particular, we need to ensure that we not only make traffic even safer, but also make drivers’ working hours less expensive. I have always thought that manoeuvring and shunting operations when loading and unloading vehicles are among the easiest tasks, and that they could be easily integrated into commercial vehicles using a level 2 or level 3 assistance system, for example. This would cut staff costs, especially during non-productive times.

Why are you so involved in these issues, what drives you personally?

We are at a point where we urgently need to achieve a breakthrough as a society, and it’s simply an amazing feeling when you know deep down inside that we are so close to making it happen, that we have the technical capabilities and the ideas to truly achieve a fundamental and revolutionary transformation in terms of both economic and environmental aspects. If you can play a bit of a part in this and perhaps also act as a catalyst here and there in order to give society and the coming generations a major advantage, then I find that to be about the most satisfying thing you can do. Especially as an engineer, who

really just wants to make the world a better place. And when the technical capabilities are more or less handed to us on a silver platter and you can just connect them together, it’s simply an amazing time and it’s great to be able to to play a part.